Water Environment (Controlled Activities) (Scotland) Regulations 2011 (as amended) govern the storage of oil, except for private dwellings storing oil for use in domestic heating or cooking in a container with a capacity of 2500 litres or less. New, substantially enlarged or substantially reconstructed fuel storage tanks and areas must conform to the standards set in the Regulations. The General Binding Rules 26, 27 and 28 specify the requirements and details can be found in the CAR practical guide.

These regulations apply to oil stored in containers both inside and outside of buildings. Including:

- Tanks

- Intermediate bulk containers

- Oil drums

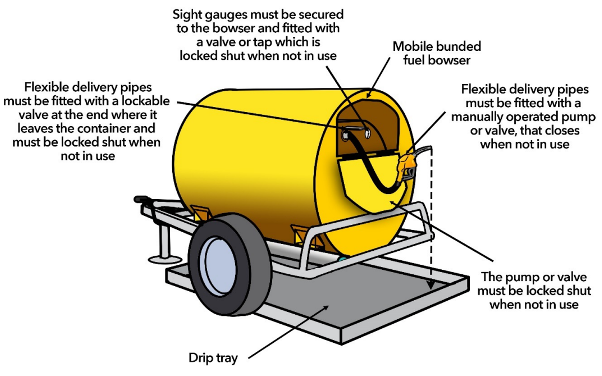

- Mobile bowsers

- Portable containers

Domestic fuel oil, which is stored separately, and underground storage tanks are not covered by the Regulations.

The Regulations on Oil Storage do not apply if:

- The oil is stored in a container wholly underground unless the container is in an underground part of a building e.g. in a basement.

- Oil is stored according to the requirements of a pollution prevention and control Part A permit.

- The oil is stored at a private dwelling in a container with a capacity of 2,500 litres or less.

- The oil is uncut bitumen (as this will solidify at normal ambient temperatures, close to any spillage).

Oil tanks connected to fixed combustion appliances, like central heating boilers and cookers, need to comply with the building regulations that apply in Scotland. For more information on above ground oil storage tanks NetRegs have produced a guidance document.

When storing oil you need to ensure that the container in which the oil is stored is capable of securely holding the material. The container must not leak or burst, be strong enough and have the capacity to store the oil.

Key resources

- Farming Water Scotland have produced a Storage of Oil Know the Rules Factsheet, which should be consulted prior to storing oil on site.

- NetRegs have a section dedicated to Oil and Fuel Storage which provides key information on how to comply with regulations.

The fuel storage area must be surrounded by a bund (a containment area around a fuel tank), an example of a secondary containment system (SCS). This bund and the base of the storage area must be impermeable to both oil and water with no drainage outlets. It should regularly be checked for leaks. Please note some tanks are integrally bunded so please check before use.

No part of the storage facility shall be within:

- 10 m of inland and coastal waters or

- 50 m of a well, spring or borehole.

This should remain compliant with the General Binding Rules 26, 27 and 28 of The Water Environment (Controlled Activities) (Scotland) Regulations 2011 (as amended) (CAR).

The floor of the storage area will normally be constructed in reinforced concrete and should drain to an internal sump. This sump will facilitate the removal of the final part of any spillage or rainwater collecting within the bund.

Any water removed from the bund, contaminated with oil, must be disposed of as special waste (information on the disposal of special waste can be found here), using an appropriately licensed waste contractor. NetRegs have complied information on bunding which can be referenced here.

The minimum bund capacities required are:

- For a single tank – 110% of the tank capacity; or

- For two or more tanks, for drums or barrels or for any combination of these with tanks – 110% of the capacity of the largest container or 25% of the total volume of oil, which could be stored in the area, whichever is the greater.

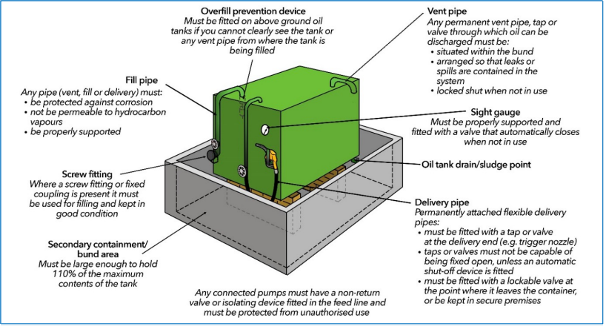

Every part of any container should be within the bund, including all taps, valves, pipes, and these must discharge downwards into the bund. Permanently attached flexible pipes must be fitted with automatic cut off taps and valves, which must be locked shut when not in use. No outlet should be provided from the bund as this could allow the escape of oil and cause a major pollution incident. The installation of new fuel tanks should be discussed with SEPA to ensure their compliance with the Regulations.

Where a fill pipe is not within the SCS, you must use a drip tray to catch any oil spilled when the container is being filled. The drip tray must be clean and empty before each delivery.

You must protect metal fill pipes, draw-off pipes or overflow pipes from corrosion and do not use pipes that are permeable to hydrocarbon vapours.

Within your system you need to provide a method for the removal of rainwater and spillages, for example, a small sump for removal by a hand pump. Providing a roof will reduce the volume of waste material collected in the sump where practical.

If pipework is underground you must ensure that it:

- Has no mechanical joints except where you can access them for inspection.

- Is protected against corrosion and from physical damage.

- Has adequate facilities for detecting leaks.

- Is not permeable to hydrocarbon vapours.

Above ground tanks must be fitted with an automatic overfill protection device (which may include an alarm sounding device) if you cannot clearly see the tank or any vent pipe from where the tank is filled.

Figure 1: Oil Storage Requirements KTR6Storage-oil.pdf (farmingandwaterscotland.org)

All oil tank(s) supports (i.e. block walls) should be contained within the bund, as shown in Figure 1. Such supports are normally comprised of concrete blockwork and can be independent of, or part of the bund. In the latter situation, they must not be as high as the bund, to avoid the risk of any spillage or leakage escaping over the top of the bund. For similar reasons, other types of tank support systems must not be carried on the wall head of the bund. Please note:

- Steel tanks should be separated from the supports on which they rest by a bitumen felt or equivalent material in order to reduce the potential for corrosion.

- Certain manufactured oil storage tanks come self-bunded, however, note that these will only satisfy the Regulations if all ancillary equipment such as sight gauges, vents etc. are within the bund and the secondary containment provides 110% capacity of the primary tank should it leak.

Your bund should be designed to reduce the risk of oil spraying beyond the containment area if your tank develops a hole (known as jetting).

Storage tanks should be labelled to describe tank capacity and fuel type, and ‘No Smoking’ signs should be displayed. All storage tanks should meet with the requirements of BS EN ISO 9001. A safe means of access to and from the bund should be provided. Facilities should be installed to enable the delivery operator to fill the fuel tank from ground level.

When planning where you are going to locate your oil storage you must ensure that you consider:

- The distance to other buildings

- Ease of access for deliveries and farm vehicles

- The proximity of drains, watercourses and water supplies.

- Ensure that you have in place suitable fire breaks between buildings and storage facilities.

It is preferable not to store fuel oils inside buildings unless the building is designed for that specific purpose.

Where possible oil should not be stored in high-risk locations; these include:

- Within 50 m of a spring, well or borehole.

- Within 10 m of a watercourse.

- Located where spilt oil could enter open drains, loose fitting manhole covers or soak into the ground.

- Located where a spill could run over hard ground to enter a watercourse or soak into the ground.

- Located where tank vent pipe outlets can’t be seen from the filling point.

- Above roof level, as spilt oil can run unseen into guttering connected to surface water systems.

- Protected areas where ground water is particularly vulnerable.

Avoid locations where spillage could contaminate other storage materials such as animal feeds. Storage of oil within catchments of public water supply, or in protected zones around underground sources for public supplies, may be prevented or restricted by bylaws.

When possible, avoid storing oil in areas at risk of flooding. If there is no alternative, consider raising any tanks above predicted flood levels, as long as this does not compromise tank integrity, safe delivery and handling of your oil. Tanks could also be secured to ensure that it does not lift as water rises around it.

Storage of waste oil.

Waste oil is classes as a special waste and will need stored and disposed of as per special waste guidelines, which can be found in the special waste section.

When carrying out machinery maintenance you must ensure that you comply with Regulations for Oil Storage. Containers that are used to store oil must be appropriately strong and robust to hold the waste oil without spillage or corrosion. The oil must be stored in an appropriate location until the oil can be disposed of by a special waste carrier.

This must satisfy the needs of delivery and farm vehicles. Good artificial lighting should be considered for the area to provide safe working conditions and for security reasons in some situations.

It is recommended that there is a minimum distance of 750 mm between the tank and the bund wall and 600 mm between the tank and the base to allow for access for external inspection and maintenance.

Areas around the store on which vehicles park to load or unload should ideally be made of concrete. If possible, the drainage gradients should be inwards to the storage area. Drains must be fitted with a suitable oil trap and some means of sealing the drain in an emergency.

Where feasible, the delivery of fuel should be supervised and only when unavoidable should ladders or steps be used. In such cases, it is essential to conform to the Health & Safety at Work Act 1974. Top openings, when used, should be provided with a suitable system to hold the filler pipe in position. Where the connection to a filler pipe is below the maximum oil level in the tank, a tap or non-return valve must be fitted to prevent spillage when the filler pipe is disconnected.

A method to indicate the level of oil in the tank should be provided. Gravity is frequently the method adopted for transferring oil from a farm storage tank and this will necessitate the tank being raised above the level of a vehicle’s fuel tank. Good working access and a trigger valve should be provided to prevent the operator overfilling the vehicle’s tank. However, if you can move to a pumped oil dispensing method as this practice reduces the chance of oil spillage.

In the case of a direct oil feed from a storage tank to fixed equipment, an automatic emergency fuel shut off system should be provided.

The storage area and bund should be regularly checked for the presence of water and oil to ascertain that there have been no failures of the structure. The bund should be frequently emptied of accumulated rainwater. The storage tank(s) and associated pipes and valves should be regularly checked for leakage.

The tank itself, if of steel, will require regular maintenance of the exterior surface.

Figure 2: Mobile bunded fuel bowser with drip tray KTR6Storage-oil.pdf (farmingandwaterscotland.org)

Related resources

Integrated Pest Management and the Voluntary Initiative

How can you improve pesticide management on farm?

How can you improve pesticide management on farm? In this podcast we chat with Neal…

Environmental and animal welfare considerations of dealing with sheep scab

This podcast focuses on how farmers can manage sheep scab. In particular discussing what farmers need to be aware of and the rules and regulations that need to be followed when managing sheep dip from animal welfare, to environmental regulation. Photo credit: ©Neil Fell